Desulfurization by Scrubber System on Ship

Scrubbers or Exhaust Gas Cleaning Systems (EGCS) are used to remove particulate matter and harmful components, such as sulphur oxides (SOx) and nitrogen oxides (NOx) from the exhaust gasses generated as a result of combustion processes in marine engines, to implement pollution control.

These scrubbing systems have been developed and employed to treat exhaust from engines, auxiliary engines and boilers, onshore and onboard marine vessels, to ensure that no damage is done to human life and the environment by toxic chemicals.

Sulphur emissions to the atmosphere by sea-going vessels are limited by new and updated international regulations, which will come into effect starting 01 January 2020 under the Marpol Treaty.

The International Maritime Organization (IMO) regulations mandate that the sulphur content in fuels, which is carried by merchant vessels, has to be limited to 0.50% globally and 0.10 % m/m in ECAs (Emission Control Areas; The Baltic Sea Area, The North Sea area, The United States, Canada, and the United States Caribbean Sea area).

Before this, the maximum sulphur cap in fuels has been kept at 3.5% m/m. Compliance with the new regulations requires that vessels either use expensive fuel with low sulphur content or clean the exhaust gases by using exhaust scrubbing systems.

Exhaust gas scrubbers are hence being installed on a substantial number of ships to comply with international regulations and standards economically.

Operational Principle of Scrubber System

Exhaust gas streams are passed inside the scrubber where an alkaline scrubbing material is present to neutralize the acidic nature of the exhaust gasses and remove any particulate matter from the exhaust.

The used-up scrubbing material is then collected with wash water which may be stored or disposed of immediately as the effluent. The cleaned exhaust is passed out of the system and into the atmosphere. The scrubbing material is chosen such that specific impurities like SOx or NOx can be removed by suitable chemical reactions.

For de-sulphurization purposes, marine scrubbers use lime or caustic soda such that sulphur-based salts are produced after treatment, which can be easily discharged as they do not pose a threat to the environment. Scrubbers may use sea water, fresh water with added calcium/sodium sorbents or pellets of hydrated lime as the scrubbing medium because of their alkaline nature.

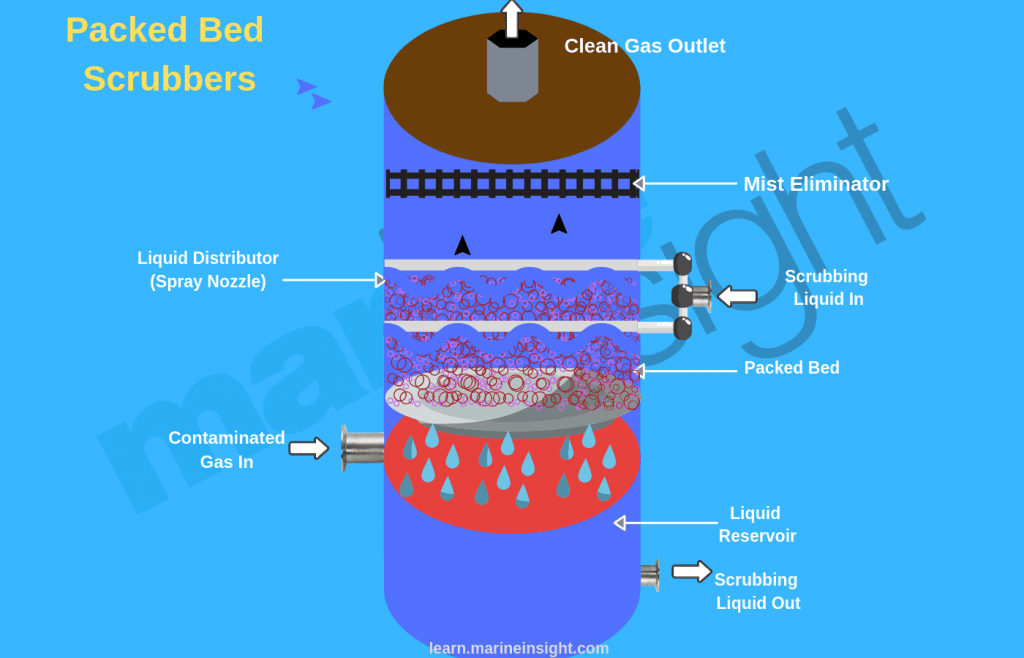

To increase the contact time between the scrubbing material and gas, packed beds consisting of gas-pollutant removal reagents (such as limestone), are used inside the scrubbers. These packed beds they slow down the vertical flow of water inside the scrubbers and intensify the exhaust gas cooling and acidic water neutralization process. Scrubbers are designed to maximize the absorption of gasses passing through it.

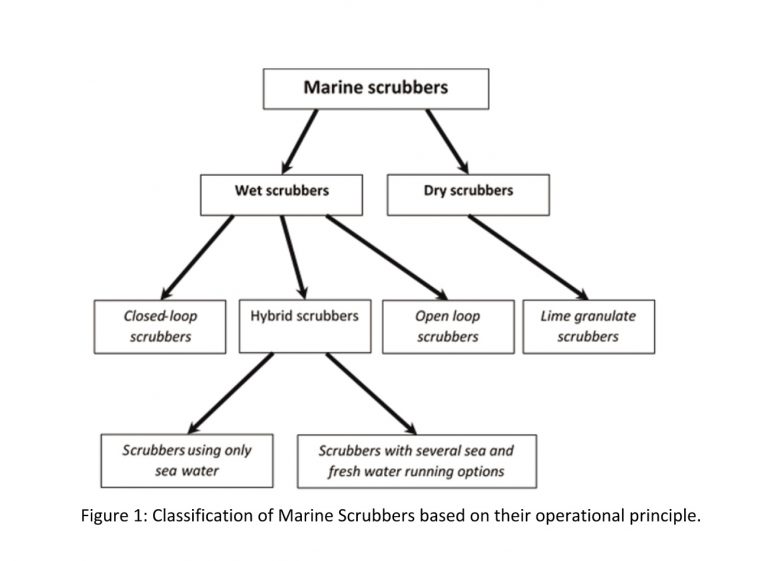

Classification of Marine Scrubbers

On the basis of their operation, marine scrubbers can be classified into Wet and Dry scrubbers. Dry scrubbers employ solid lime as the alkaline scrubbing material which removes sulphur dioxide from exhaust gasses. Wet scrubbers use water which is sprayed into the exhaust gas for the same purpose.

Wet scrubbers are further classified into closed-loop or open loop scrubbers. In close looped scrubbers, fresh water or sea water can be used as the scrubbing liquid. When Fresh water is used in closed loop scrubbers, the quality of water surrounding the ship has no effect on the performance and the effluent emissions of the scrubber. Open-loop scrubbers consume sea water in the scrubbing process.

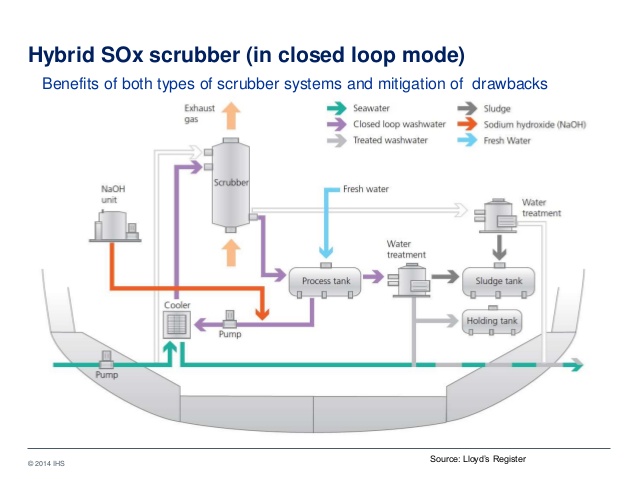

Hybrid scrubbers can utilise both closed and open running modes either at the same time or by switching between the two. Seawater hybrid scrubbers can be operated both in closed or open mode with seawater used as the scrubbing medium.

Wet Scrubbers

Inside a wet scrubber, the scrubbing liquid used may be sea water or fresh water with chemical additives. The most commonly used additives used are caustic soda (NaOH) and Limestone (CaCO3). Scrubbing liquid is sprayed into the exhaust gas stream through nozzles to distribute it effectively. In most scrubbers the design is such that the scrubbing liquid moves downstream, however, scrubbers with an upstream movement of scrubbing liquids are available as well.

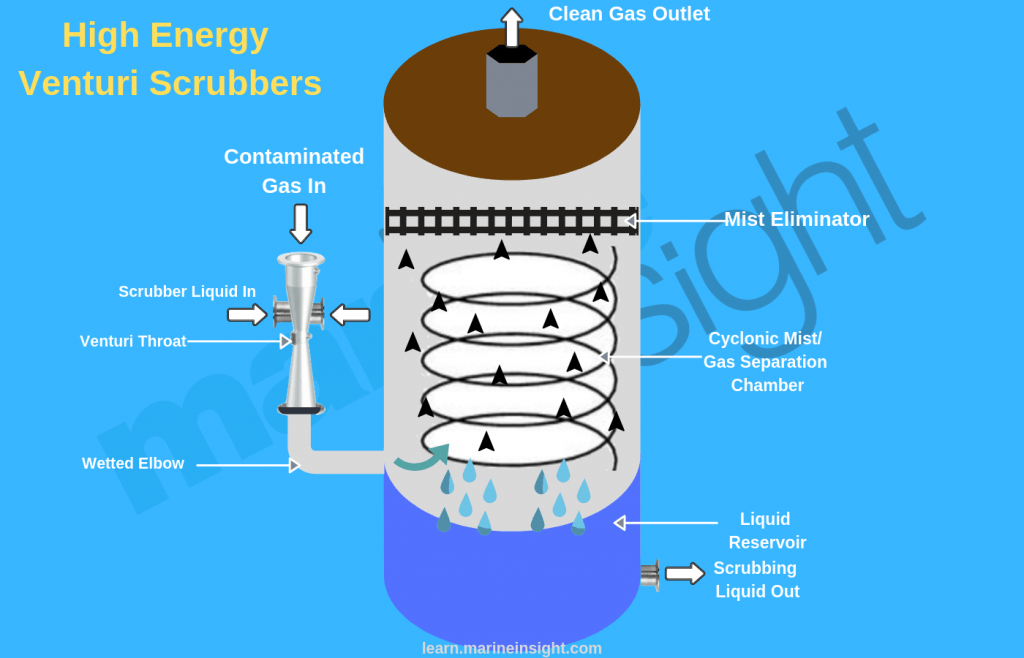

The exhaust inlet of the scrubber can be made in the form of a venturi, as shown in Figure 2.1, in which the gas enters at the top and water is sprayed in the high exhaust gas speed areas at the neck or above the neck in the form of a spray. An inline scrubber is shown in figure 2.2.

The exhaust intake is either on the side or the bottom of the tower. The designs ensure that the sulphur oxides present in the exhaust are passed through the scrubbing liquid; reacting with it to form sulphuric acid. When diluted with alkaline seawater, sulphuric acid which is highly corrosive in nature can be neutralised.

The wash water is discharged into the open sea after being treated in a separator to remove any sludge from it and the cleaned exhaust passes out of the system. Mist eliminators are used in scrubbing towers to remove any acid mist that forms in the chamber by separating droplets that are present in the inlet gas from the outlet gas stream.

MARPOL regulations require that the wash water used has to be monitored before being discharged to ensure that its PH value is not too low. Since the alkalinity of seawater varies due to the number of reasons such as the distance from land, volcanic activity, marine life present in it etc, wet scrubbers are divided into two types; open loop and closed loop systems. Both these systems have been combined into a hybrid system, which can employ the most suitable scrubbing action depending upon the conditions of the voyage.

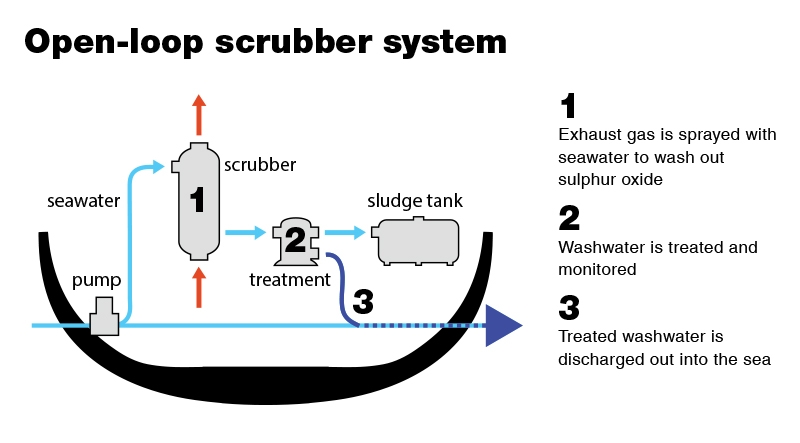

Open Loop Scrubber System

This system uses seawater as the scrubbing and neutralising medium, no other chemicals are required for desulphurization of gasses. The exhaust stream from the engine or boiler passes into the scrubber and is treated with only alkaline seawater only. The volume of this seawater depends upon the size of the engine and its power output.

The system is extremely effective but requires large pumping capacity as the amount of seawater required is quite high. An open loop system works perfectly satisfactorily when the seawater used for scrubbing has sufficient alkalinity. However, sea water which is at high ambient temperature, fresh water and even brackish water, is not effective and cannot be used. An open loop scrubber for these reasons is not considered as a suitable technology for areas such as the Baltic where salinity levels are not high.

Reactions Involved:

SO2 (gas) + H2O + ½O2 → SO4 2- + 2H+ (Sulphate ion + Hydrogen ion)

HCO3– + H+ → CO2 + H2O (Carbon-di-oxide + Water)

Advantages:

1. It has very few moving parts, the design is simple and easy to install on board.

2. Apart from de-fouling and operational checks, the system requires very less maintenance

3. This system does not require storage for waste materials

Disadvantages:

Cooling of the exhaust gas is a problem faced by wet scrubber systems.

2. The operation of the system depends upon the alkalinity of water available and is not suitable to 3. be employed in all conditions.

4. A very large volume of sea water is required to obtain efficient cleaning and hence the system consumes very high power.

5. In ECA zones and ports, higher costing fuel has to be consumed.

Closed Loop Scrubber System

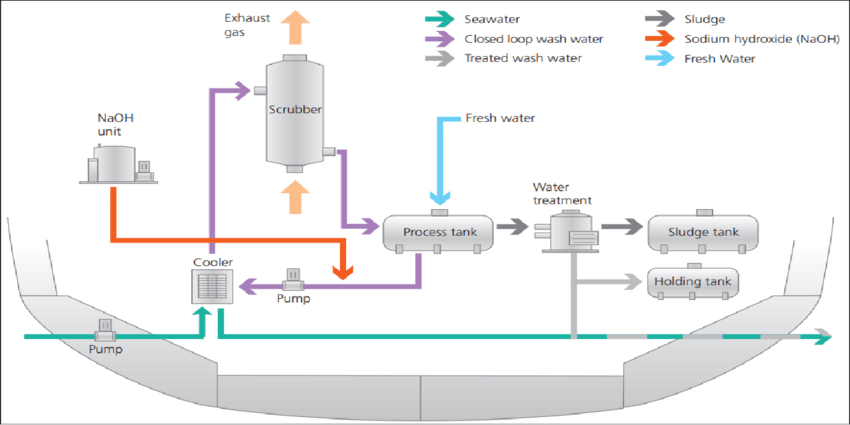

It works on similar principals to an open loop system; it uses fresh water treated with a chemical (usually sodium hydroxide) instead of seawater as the scrubbing media. The SOx from the exhaust gas stream is converted into harmless sodium sulphate. Before being re-circulated for use, the wash water from a closed loop scrubber system is passed through a process tank where it is cleaned.

The process tank is also needed for the operation of a circulation pump that prevents pump suction pressure from sinking too low.

Ships can either carry fresh water in tanks or generate the required water from freshwater generators present on board. Small amounts of wash water are removed at regular intervals to holding tanks where fresh water can be added to avoid the build-up of sodium sulphate in the system.

A closed-loop system requires almost half the volume of wash water than that of the open loop version, however, more tanks are required. These include a process tank or buffer tank, a holding tank through which discharge to sea is prohibited and also a storage tank capable of regulating its temperature between 20º and 50ºC for the sodium hydroxide which is usually used as a 50% aqueous solution.

Dry sodium hydroxide also requires large storage space. The hybrid system is a combination of both wet types that can operate as an open loop system when water conditions and the discharge regulations allow and as a closed loop system at other times. Hybrid systems are hence proving to be the most popular because of their ability to cope with different conditions.

Reactions Involved

2NaOH + SO2 → Na2SO3 + H2O (Sodium Sulphite);

Na2SO3 +SO2 +H2O → 2NaHSO3 (Sodium Hydrogen Sulphite);

SO2 (gas) + H2O + ½O2 → SO42- + 2H+ ;

NaOH + H2SO4 → NaHSO4 + H2O (Sodium Hydrogen Sulphate);

2NaOH + H2SO4 → Na2SO4 + 2H2O (Sodium Sulphate).

Advantages:

1. Very less maintenance is required.

2. It is independent of the operating environment of the vessel.

3. Cooling of exhaust gas is a problem with wet scrubbing systems.

Disadvantages

It requires storage space (buffer tank) to hold waste water until it can be discharged

2. Selective catalytic reduction systems must operate before wet scrubbers.

Fitting the system together, especially for dual-fuel engines can be quite complex.

Hybrid Scrubber System

These systems offer a simple solution for retrofitting vessels with scrubbers that are capable of operation on both open loop and closed loop configurations. These systems run on open loop mode at sea and closed loop mode in ECA zones and ports and their use can be switched with ease. As the system can run on lower costing fuels for longer periods of time and around the world, they can overcome their high initial costs in order to economically meet with the international regulations.

Advantages:

Suitable for long and short voyages around the world

Ships with Hybrid scrubbing systems can spend more time in ECA zones and on port than those with open loop systems

3. Can use lower costing HFO (Heavy Fuel Oil) all of the time.

Disadvantages

1. More structural modifications are needed to employ this system.

2. Requires large storage space for chemicals and additives.

3. The system has a high installation time and cost.

Dry Scrubbers

In these types of scrubbers, water is not used as a scrubbing material, instead, pellets of hydrated lime are used to remove sulphur.

The scrubbers are at a high temperature than their wet counterparts and this has a benefit that the scrubber burns off any soot and oily residues in the system. The calcium present in caustic lime granulates reacts with the sulphur dioxide in the exhaust gas to form calcium sulphite.

Calcium sulphite is then air-oxidized to form calcium sulphate dehydrate, which with water forms gypsum. The used pellets are stored on board for discharge at ports, however, they are not considered a waste as the gypsum formed can be used as a fertiliser and as construction material.

Dry scrubber systems consume less power than wet systems as they do not require circulation pumps. However, they weigh much more than wet systems.

Reactions Involved

SO2 + Ca(OH)2 → CaSO3 + H2O (Calcium Sulphite)

CaSO3 + ½O2 → CaSO4 (Calcium Sulphate)

SO3 + Ca(OH)2 → CaSO4 + H2O (Gysum)

Advantages

1. There is efficient removal of nitrogen and sulphur oxides

2. This type of system does not result in the production of liquid effluent that must be disposed of overboard.

3. The Gypsum obtained after the exhaust gas cleaning process can be sold for use in various industrial applications

Disadvantages

They require significant onboard storage to handle the dry bulk reactants and products associated with the process.

There must be a readily available supply of the reactants.

the reactants used are costly, especially urea for NOx abatement and calcium hydroxide for SOx abatement

Choice of Scrubber System

In order for a shipping company to select the most suitable kind of scrubber system to be installed on board, there are many factors it must consider. These include; the installation spaces available on board, the area of operation and the chartering schedule of the ship, the power and output of the engine and boiler on board, the availability of fresh water on board and the available power on board to run the system in different conditions, amongst others.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.