Specialized Distillation Column Internal Design & Engineering Services

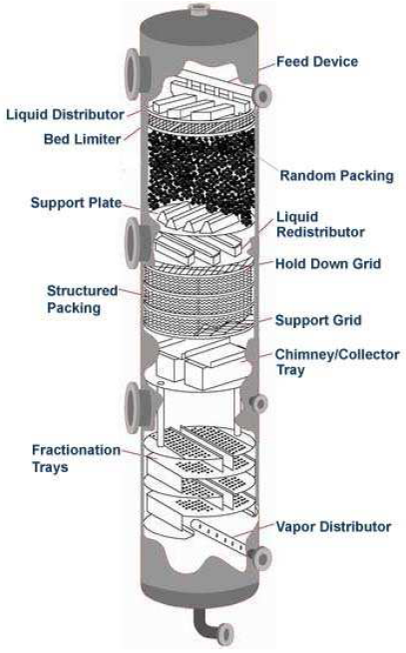

In oil, gas, petrochemical, and refining industries, distillation columns are among the most critical and complex process equipment. The optimal and stable performance of these units depends on precise design of internal components. Our technical engineering team, utilizing modern chemical engineering knowledge and practical experience in industrial projects, provides design, selection, and optimization services for distillation column internals with the highest quality and accuracy standards.

Why is Distillation Column Internal Design Important?

Proper design of distillation column internals including trays, packings, distributors, reboilers, and diffusers directly impacts separation efficiency, energy consumption reduction, operational capacity, and equipment lifespan.

- Low separation efficiency

- Excessive pressure drop

- Phenomena like flooding, weeping or entrainment

- Reduced equipment lifespan

- Increased operational costs

Our Service Offerings:

1. Complete Mechanical & Process Design of Internals

- Column Trays (Bubble Cap, Sieve, Valve Trays)

- Structured & Random Packings

- Liquid and Gas Distributors & Collectors

- Gas Diffusers (Perforated Pipes, Chimney Trays)

- Reboilers (Thermosyphon, Kettle, Forced Circulation)

- Condensers (Total and Partial)

2. Pressure Drop and Separation Efficiency Modeling

- Complete hydraulic calculations (Flooding Point, Weeping Point, Pressure Drop)

- Design based on API, TEMA, GPSA, and Perry’s Handbook standards

- Gas and liquid loading capacity analysis

3. Engineering Software Design & Simulation

- ASPEN Plus, HYSYS for process modeling

- CAD and 3D software for precise mechanical design

4. Redesign & Optimization of Existing Columns

- Operational problem diagnosis

- Capacity increase without complete column replacement

- Utility (steam) consumption reduction

Our Engineering Design Approach:

- Process Data Analysis: Feed, products, pressure, temperature, flow rates and material composition review.

- Optimal Internal Selection: Tray or packing based on operational conditions.

- Hydraulic Calculations: Determining column diameter, hole type, gas velocity etc.

- Pressure Drop Analysis: Calculating pressure drop in trays, packings and perforated pipes.

- Gas Compressibility: Mach Number and choked flow analysis.

- Design Validation: Using Perry, Ludwig and industrial standards.

Benefits of Working With Us:

- Experience designing over 50 distillation columns

- Collaboration with major oil & gas clients

- Complete and verifiable calculation reports

- Technical support during implementation and startup

Our Target Clients:

- Refineries

- NGL and LNG units

- Petrochemical plants

- Engineering design companies

- Process equipment manufacturers

Sample Completed Projects:

- Internal design and modification for South Refinery column

- Perforated pipe design for Stabilizer unit

- Capacity increase for NGL separation column

For Free Consultation or Service Order:

Contact us through the website form, email or phone number.

Contact us to entrust your distillation column internal design with confidence and precision.